Quantum-Inspired Optimization in Manufacturing

Revolutionizing production efficiency through novel algorithmic approaches Quantum-inspired optimization is emerging as a groundbreaking technique in manufacturing, offering solutions to complex operational challenges that traditional methods struggle to address. This innovative approach borrows concepts from quantum computing to enhance classical algorithms, enabling manufacturers to tackle intricate scheduling, resource allocation, and supply chain optimization problems with unprecedented speed and accuracy. As industries seek to maximize efficiency in an increasingly competitive global market, quantum-inspired optimization stands poised to redefine the boundaries of manufacturing capabilities.

Tackling Complex Manufacturing Challenges

In the realm of manufacturing, optimization problems often involve an astronomical number of variables and constraints. Traditional optimization methods can struggle with these complexities, sometimes taking days or even weeks to compute optimal solutions. Quantum-inspired algorithms, however, can navigate these vast solution spaces more efficiently, often finding near-optimal solutions in a fraction of the time. This capability is particularly valuable in dynamic manufacturing environments where rapid decision-making is crucial.

Enhancing Production Scheduling

One of the most promising applications of quantum-inspired optimization in manufacturing is in production scheduling. These algorithms can quickly analyze numerous factors such as machine availability, order priorities, material constraints, and delivery deadlines to generate optimized production schedules. By considering a wider range of possibilities simultaneously, quantum-inspired methods can uncover scheduling solutions that minimize downtime, reduce waste, and improve overall productivity.

Optimizing Supply Chain Logistics

The complex web of suppliers, distributors, and transportation networks in modern supply chains presents another ideal scenario for quantum-inspired optimization. These algorithms can process vast amounts of data to optimize inventory levels, transportation routes, and distribution center locations. By doing so, manufacturers can significantly reduce costs, improve delivery times, and enhance their resilience to supply chain disruptions.

Energy Efficiency and Sustainability

As industries face increasing pressure to reduce their environmental impact, quantum-inspired optimization offers a powerful tool for enhancing energy efficiency in manufacturing processes. These algorithms can analyze energy consumption patterns across entire production lines, optimizing operations to minimize energy use without compromising output. This not only reduces costs but also helps manufacturers meet sustainability goals and regulatory requirements.

Practical Insights for Implementation

• Start small: Begin with pilot projects in specific areas of manufacturing to demonstrate value before scaling.

• Collaborate with experts: Partner with quantum computing specialists to tailor algorithms to your specific manufacturing challenges.

• Invest in data infrastructure: Ensure your data collection and management systems can support the data-intensive nature of quantum-inspired algorithms.

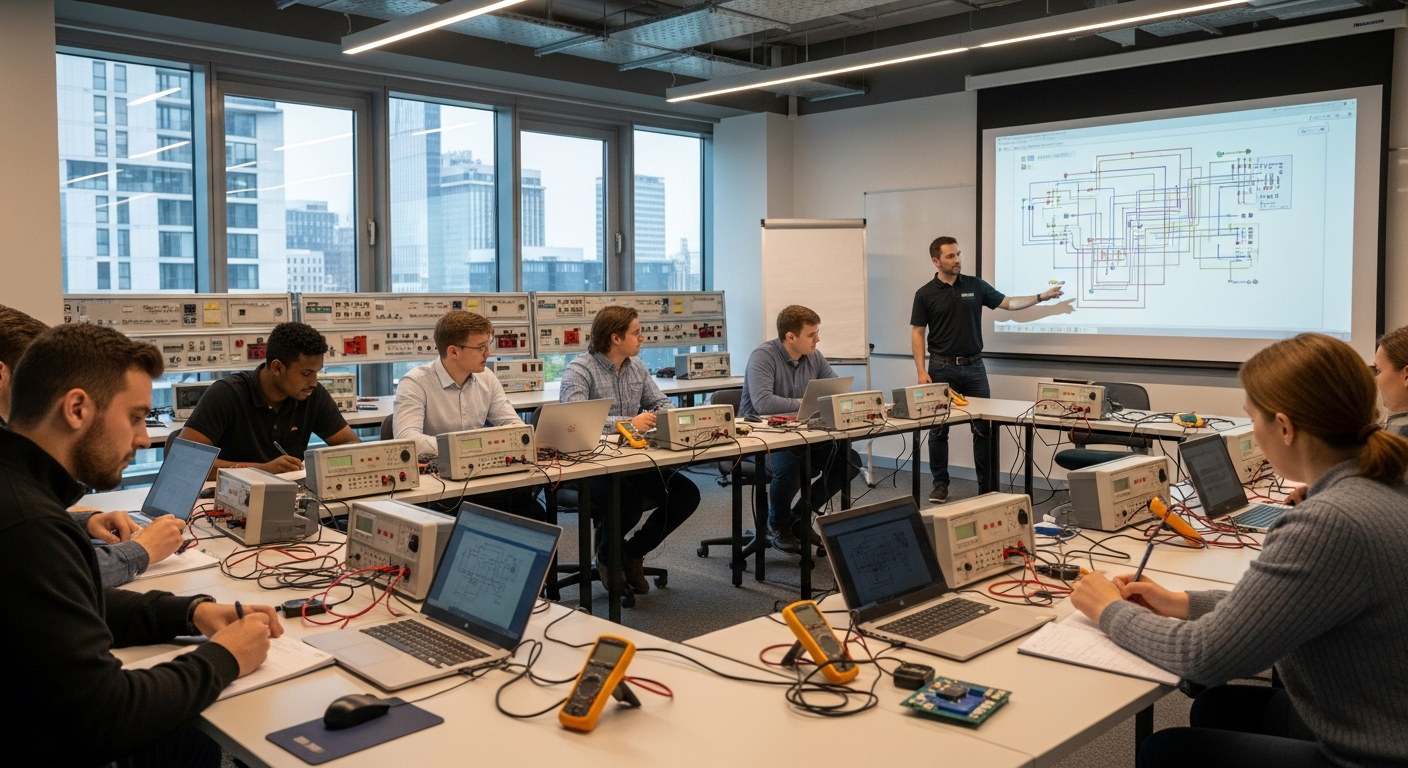

• Train your workforce: Develop in-house expertise to maximize the potential of quantum-inspired optimization tools.

• Stay adaptable: As the field evolves rapidly, maintain flexibility in your approach to incorporate new advancements.

As manufacturing continues to evolve in the face of global challenges and technological advancements, quantum-inspired optimization stands out as a transformative force. By harnessing the power of quantum principles in classical systems, manufacturers can unlock new levels of efficiency, agility, and innovation. While the journey of implementation may present challenges, the potential rewards in terms of operational excellence and competitive advantage make quantum-inspired optimization a compelling frontier for forward-thinking manufacturers to explore.