Resource Efficiency in Industrial Operations

Industrial operations worldwide are increasingly focusing on resource efficiency as a critical component of sustainable growth and competitive advantage. This approach involves optimizing the use of raw materials, energy, water, and other inputs across all stages of production, from initial sourcing to final delivery. By minimizing waste and maximizing output from every resource, businesses can reduce operational costs, lessen their environmental footprint, and enhance their overall resilience in a dynamic global market. Understanding the multifaceted aspects of resource efficiency is key for enterprises aiming to thrive in today's economic landscape.

Optimizing Manufacturing and Production Processes

At the core of industrial operations, manufacturing and production processes offer substantial opportunities for resource efficiency. This involves a systematic review of existing workflows to identify areas where material or energy consumption can be reduced without compromising quality or output. Techniques such as lean manufacturing, which focuses on eliminating waste in all forms, and Six Sigma, which aims to reduce defects and variability, are instrumental. Implementing process improvements, such as optimizing machine run times, reducing scrap rates, and improving energy management in facilities, directly contributes to more efficient resource utilization.

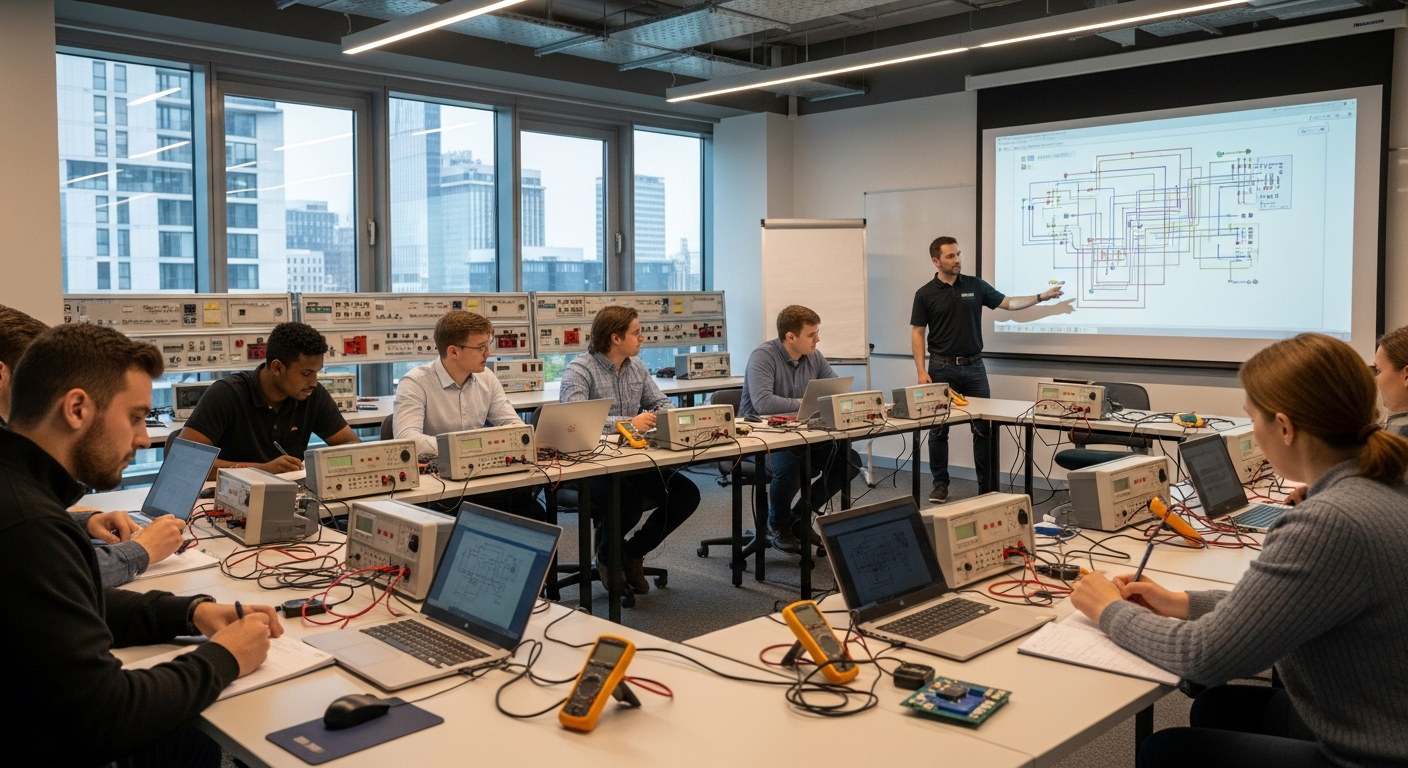

Leveraging Technology and Automation for Efficiency

Technology and automation play a pivotal role in driving resource efficiency. Advanced manufacturing technologies, including robotics, artificial intelligence, and the Internet of Things (IoT), enable precise control over production processes, reducing human error and optimizing resource allocation. Automated systems can monitor energy consumption in real-time, detect equipment malfunctions before they lead to significant waste, and adjust production parameters for optimal material use. Digital twins, for instance, allow for virtual testing and optimization of processes, minimizing physical prototypes and associated material waste. The integration of such technologies can transform traditional operations into highly efficient and data-driven enterprises.

Enhancing Supply Chain and Logistics Resilience

Resource efficiency extends beyond the factory floor into the broader supply chain and logistics network. An efficient supply chain minimizes waste from excessive inventory, optimizes transportation routes to reduce fuel consumption, and promotes the use of sustainable packaging materials. Building resilience in the supply chain means anticipating disruptions and having strategies in place to mitigate their impact on resource availability and flow. This includes diversifying suppliers, implementing robust inventory management systems, and exploring localized sourcing options. Effective logistics management ensures that resources are moved efficiently, reducing both costs and environmental impact, while also safeguarding against potential market volatilities.

Integrating Digital Processes for Sustainable Growth

The adoption of digital processes is fundamental for achieving sustainable growth through enhanced resource efficiency. Digitalization enables comprehensive data collection and analysis across all operational facets, providing insights into resource consumption patterns, waste generation, and potential areas for improvement. Enterprise Resource Planning (ERP) systems, for example, integrate various business functions, allowing for better planning, control, and optimization of resources from raw materials to finished goods. This holistic approach supports informed decision-making, fosters continuous improvement, and underpins strategies for long-term sustainability and growth in a global context.

Strategies for Innovation and Development

Innovation and continuous development are crucial for sustaining and advancing resource efficiency initiatives. This includes investing in research and development for new materials that are more sustainable or require less energy to produce, as well as developing novel production methods that are inherently more efficient. Encouraging a culture of innovation within an organization can lead to breakthroughs in waste reduction, energy recovery, and product design for circularity. Strategic development also involves collaborating with partners across the value chain to collectively improve resource use and promote industry-wide best practices, ensuring that businesses remain competitive and adaptable to evolving market demands and environmental regulations.

Global Market Dynamics and Resource Management

Navigating the complexities of the global market requires a strategic approach to resource management. Fluctuations in commodity prices, geopolitical events, and evolving trade policies can significantly impact the availability and cost of resources. Industrial operations must develop resilient strategies that account for these global dynamics, such as diversifying sourcing locations, hedging against price volatility, and exploring circular economy models that minimize reliance on virgin resources. Understanding global market trends and anticipating future resource demands are essential for maintaining operational stability and ensuring long-term competitiveness.

Resource efficiency in industrial operations is a comprehensive endeavor that requires a holistic approach, integrating process optimization, technological advancements, supply chain resilience, digital transformation, and continuous innovation. By strategically managing resources, enterprises can not only reduce their operational footprint and enhance sustainability but also secure a stronger position in the competitive global market. This ongoing commitment to efficiency is vital for fostering economic growth and ensuring environmental stewardship.